To correct, increase the air pressure (to no more than 90 PSI) and/ or replace the worn Nozzle. blaster pressure alc allsource Keep the input valve and air control valve wide open at all times when blasting. Designate a work area that is clean and well-lit.

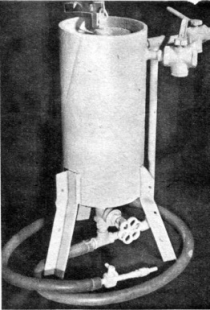

Equipped with a nozzle end shut-off valve, pressure gauge, ceramic nozzle, 9 foot hose, filling funnel, water trap, 6" rubber wheels, and canvas hood. I didn't like the heavy spring loaded blast control valve. Greater distance gives a larger blast spot for quicker progress.

Central Pneumatic Series 40 Lb Pressurized Sandblaster Model 34202 Assembly and Operating Instructions.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation of exclusion may not apply to you.THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND FITNESS.To take advantage of this warranty, the product or part must be returned to us with transportation charges prepaid. Open the Media Valve. ?,)rD&7hgq/X~s(8$b+>gT ?iadZgg[%C'Btt;LL|D( IEZT{%"F$Z)D?DCS*NEB('TF8*Du1@!d$4 Even then you would have your hair and ears full of gritty dust. shape or form without the express written consent of Harbor Freight Tools.

Addresses practices not related to personal injury. After doing some blasting in my 16x21 foot shop space, the place at first appeared to be a horrible mess with about 20 pounds of grit and dust on the floor and all over everything, including inside the car. Air consumption for the blaster will be nearly proportional to the pressure being used. Water Trap Refer to Figure 2. I didn't like the heavy handed operation of the control lever, so this may be better if it was changed to a ball valve. eastwood With pressure still on the blast head you may poke a wire into the ceramic nozzle, and with luck this may clear the clog. esb sabbiatrice pneumatica sandblaster pneumatique sableuse epi eurocem medicalexpo %PDF-1.6 % Empty the Tank, and clean external surfaces of the Soda Blaster with clean, dry cloth. Always disconnect the air supply and relieve tank pressure before attempting to remove the top fill cap from the media tank. The shop vac will clean a smooth floor in a single pass.

Hold collar on Tank (1) with a wrench and use another wrench to loosen Bushing (10). ftypjp2 jp2 jpxbjpx rreq @ - Ojp2h ihdr J colr pclr wwwvvvuuurrrssstttiiiccceeebbbaaa```___^^^]]]WWWQQQRRRNNNMMMLLLKKKIIIlllVVVSSSEEECCC999222+++&&&'''$$$""" !!!###%%%444xxxXXXGGG;;;***((()))---000///111555,,,HHH333PPP?? MAINTAIN TOOLS WITH CARE. Longer trigger time goes to lower pressure until it gets too slow be useful, then stop and wait for pressure recovery. Indicates a hazardous situation which, if not avoided,will result in death or serious injury. 10. Be nice and clean any grit away from the O-ring gland to preserve life of the seal. blaster sand homemade homemadetools advertisement sandblaster Coarser material tends to clog up the nozzle on smaller blaster units (including this one). Allow time for the trapped aggregate to safely discharge back into the Tank. TO PREVENT SEriOUSINJURY:Do not adjust or tamper with any control or component in a way not specifically explained within this manual.

hbbd```b`` D(HT x4DDT@d "YK&HI@|=[`3Fg` x& endstream endobj startxref 0 %%EOF 104 0 obj <>stream Note: These procedures are in addition to the regular checks and maintenance explained as part of the regular operation of the air-operated Soda Blaster. WARNING When using tools, basic precautions should always be followed, including the following: To reduce the risks of electric shock, fire, and injury to persons, read all the instructions before using the tool. 110 lb. If you find the blaster to work well at 80-90 psi, you may want to reduce the input supply pressure not to exceed 90 psi, as higher pressure will consume more air than necessary and reduce productivity (available trigger time). blast cabinet abrasive lb capacity floor Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all text under subheadings therein before set up or use of this product. If the blast nozzle becomes clogged during use, immediately close the media control valve at bottom of the tank. If the Soda Blaster will not be used at this time, turn off and detach the air supply, safely discharge any residual air pressure, and close the valves to prevent accidental operation. X"&%2dtvE= 'Fd1UOS*{I_IGA0'HfH:(Jv|f E-q|ujt ~ ?

Adjust the air compressors output regulator so that the air output is enough to properly power the Soda Blaster, but the output will not exceed the Soda Blasters maximum air pressure at any time. "Black Beauty" (a registered trademark of Harsco Corporation): A coal slag abrasive material for use in removing paint and rust from steel and concrete.

Keep tools sharp and clean for better and safer performance.

Right Handle (#6-R) Handle Grip (#7) Handle Bar Left Handle (#6) (#6-L) Screw (#8) Washer (#31) Nut (#9) Figure 7 Handle Bar Assembly Step1: Get out the two HANDLE BARS (#6), the two HANDLE GRIPS (#5), the four SCREWS (#8), four NUTS (#9), and four WASHERS (#31). Step 4: Make sure the PRESSURE GAUGE (#15) reads 0. Of course always wear gloves and face protection, and never get your face in front of the blast nozzle. Check for: 2. A +b-|u!n p2wT,BYu.;R^~P\ -`J{tqeojJS+Aj4KAjP At 50 psi this unit stops supplying abrasive material. Do not use sand or other blasting materials that contain crystalline silica.Note: Use only dry and clean abrasives to avoid clogging the Soda Blaster.Note: The Nozzle size depends on grit of media used. If that gets the hose clear you can turn the blast head around and use the air pressure to back flush the blast head (with the head valve open), then reassemble the head to hose and reinstall the nozzle. I bought 70 grit "aggressive abrasive" for "remove paint and rust". cabinet blast pneumatic central floor lb sandblast capacity sand blasting sandblasting grizzly benchtop cheap tools coating powder Copyright 2020 by Harbor Freight Tools. 40 LB. Wear ANSI-approved eye protection. To test, check the abrasive by pouring a 6 cone of abrasive on dry newspaper. At time of this writing the canvas hood and filling funnel are missing. Otherwise, isolate the workpiece to make sure no damage can occur to nearby personal property. A rather LARGE air compressor is best to run the blaster. Attach Bracket (3) to the Tank (1) using the two Socket Head Screws (4) and wrench tighten.

Step 5: Attach the other WHEEL to the AXLE using the remaining COTTER PINS. Instructions Pertaining To A Risk Of Fire, Electric Shock, Or Injury To Persons. At the output working end of the hose is the nozzle control valve in the blaster head (which is not a ball valve here but could be for other blaster models).

The work area must not allow access by children or pets to prevent distraction and injury. Handle Bars Refer to Figure 7. any other condition that may affect its safe operation. blaster sand blasting dual abrasive soda tank sandblaster baking twin lb air portable projects central handtoolskit tools freight harbor special Poor or irregular flow of the abrasive may also be due to low air pressure or a worn Nozzle. Screw the Pressure Gauge into the opening in the face of the Air Regulator (9). SAVE THIS MANUAL You will need the manual for the safety warnings and cautions, assembly instructions, operating procedures, maintenance procedures, trouble shooting, parts list, and diagram. Do not yank compressors cord to disconnect it from the receptacle. pressurized abrasive lb pneumatic itc coupons valid diy sandblaster blaster plans sand soda sandblasting sandblast homemade cabinet tools result pressure pot gun herramientas equipment herreria compressor soldadura  Repeated or long-term exposure to vibration may cause temporary or permanent physical injury, particularly to the hands, arms and shoulders.

Provide workers with training that includes information about health effects, work practices and protective equipment for crystalline silica. Obey all safety messages that follow this symbol to avoid possible injury or death. Adjust the pressure gradually, while checking the air output gauge to set the right pressure range. Step 3: Attach one of the WHEELS to the AXLE using one of the COTTER PINS.

Repeated or long-term exposure to vibration may cause temporary or permanent physical injury, particularly to the hands, arms and shoulders.

Provide workers with training that includes information about health effects, work practices and protective equipment for crystalline silica. Obey all safety messages that follow this symbol to avoid possible injury or death. Adjust the pressure gradually, while checking the air output gauge to set the right pressure range. Step 3: Attach one of the WHEELS to the AXLE using one of the COTTER PINS.

Pregnant women or people who have impaired blood circulation to the hand, past hand injuries, nervous system disorders, diabetes, or Raynauds Disease should not use this tool. Do not smoke during use. At 60 psi it will work to remove paint and mild rust, but it works much better (more aggressively) with 75-psi or higher pressure. Cautions and Warnings first:

Follow instructions for lubricating and changing accessories. Tank (#1) Step2: Attach one of the NIPPLE CONNECTORS to the bottom of the TANK (#1). Step2: Attach the 3/8" NIPPLE CONNECTORS to either side of the WATER TRAP. After several minutes, remove the abrasive from the newspaper. That pressure is non functional with this unit, but it indicates a rough air consumption figure of 9.0-scfm @ 45-psi. HWmo+/T(PWJrmQ8Hld3Iz

A broom handle makes a good dipstick for checking media level in the tank. Prohibit silica sand (or other substances containing more than 1% crystalline silica) as an abrasive blasting material and substitute less hazardous materials.

abrasive blaster pressurized If you want to sweep up and recycle the abrasive media you would need to sift it through a window screen to remove any large trash particles that would clog up the blast nozzle. Do not tighten yet. ASSEMBLY NOTE: Use Teflon Pipe Tape on all threaded joints. b rbGGCGFG 6F 03]G89e| 0cu Cy @ MX> 0KW

endstream

endobj

76 0 obj

<>

endobj

77 0 obj

<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/Type/Page>>

endobj

78 0 obj

<>stream

It would have been better if the bonnet and boot lid were in place to keep most of the grit out of the boot and engine bay, but that didn't bother me much with the body coming off anyway. DO NOT ABUSE THE POWER CORD. Home HARBOR FREIGHT HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster. Do not attempt any repairs to the Sandblaster until its gauge reads 0. Close the in-line shutoff valve between the compressor and the Soda Blaster. Description and air requirements:

Nipple Connector (#16) Joint Pipe (#13) Air Cap (#12) Gasket (#11) Tank (#1) Nipple Connector (#16) Air Hose (#21) Figure 6 Top Assembly Step1: Get the Intake Valve Assembly, the Water Trap Assembly, the Tank Assembly, the TANK CAP (#12), the O-RING (#11), and the AIR HOSE (#21).

3 2 3 5 2 4 3 Figure 8 - Wheel and Foot Attachment Step 1: Get out the two WHEELS (#2), the three COTTER PINS (#3), the FOOT (#4) and the AXLE (#5). Step1: Get out the INTAKE MANIFOLD (#14), PRESSURE GAUGE (#15), BRASS THROTTLING VALVE (#18A), 3/8" 1/4" NIPPLE CONNECTOR (#20), and JOINT PIPE (#13). 3/8 x 13 air belt sander with accessories (13 pages), 2-3/4" x 17-1/2" air inline sander (15 pages), 6" composite palm grop random orbital santer (16 pages), Air wet  It may be appropriate to order a replacement hose for the inside of this control head, along with a few spare ceramic nozzles. Post signs to warn workers about the hazard and to inform them about required protective equipment. Parts may not be interchangeable. Pull back on the blue Air Hose Connector (8) collar and pull out Air Hose (15). All rights reserved. The grit was mostly limited to areas below shoulder level where it's not hard to reach, except it gets underneath things that need to be moved for clean up.

It may be appropriate to order a replacement hose for the inside of this control head, along with a few spare ceramic nozzles. Post signs to warn workers about the hazard and to inform them about required protective equipment. Parts may not be interchangeable. Pull back on the blue Air Hose Connector (8) collar and pull out Air Hose (15). All rights reserved. The grit was mostly limited to areas below shoulder level where it's not hard to reach, except it gets underneath things that need to be moved for clean up.

Wrap the threads of the Pressure Gauge (7) with thread sealer tape (not included). There will be no attempt here to turn an amateur blast operator into a skilled professional by words alone. I was walking around in the grit and not wanting to touch anything. on HARBOR FREIGHT 60801/60802 Central Pneumatic Portable Soda Blaster Owners Manual, HARBOR FREIGHT 62355 Central Pneumatic 1 Inch Pistol Grip Air Impact Wrench Owners Manual, Harbor Freight BADLAND WINCHES 120V AC Electric Winch Owners Manual, HARBOR FREIGHT 60801 Portable Soda Blaster Owner's Manual, HARBOR FREIGHT 42858 3 Inch Twisted Wire Brush Instructions, HARBOR FREIGHT DIY GIANT BLOCK GAME User Manual, HARBOR FREIGHT 57808 2 Amp Variable Speed Oscillating Multi Tool Owner's Manual, TRIPP LITE PDUMH Series Metered Rack PDU with Automatic Transfer Switch Owners Manual, AJAX 8706 KeyPad Wireless Touch Keyboard User Manual, Meizhou Hongfeng Arts Crafts 266285 BJ 57IN Snowman With Snowflakes Instruction Manual, AJAX 7661 StreetSiren Wireless Outdoor Siren User Manual, AJAX 17938 12V PSU for Hub/Hub Plus/ReX Power Supply Unit User Manual, ZERFUN G8 Pro Wireless Microphone System User Manual, Airrex Infrared Heater AH-200/300/800 User Manual, 2017 Toyota Camry Hybrid LE Fuse Box Diagrams, 2017 Mitsubishi Lancer 4WD Fuse Box Diagrams, Mitsubishi Lancer Passenger and Engine Fuse Box Diagram, Mira Honesty ERD Bar Valve and Fittings User Manual, Cubic Feet per Minute flow at standard conditions.

Working CFM: 6 to 25

Instructions with the sand blaster call for using a hood, which is a canvas full head cover with a clear shield in front. 23n`H`3`0c`0u#"2W/

3f@4. There is an air supply shut-off valve at the input air coupler, followed by a water separator filter and pressure gauge. Step3: Attach both HANDLE BARS to the TANK (#1) using the four SCREWS, NUTS, and WASHERS. Notice the pressure rating and air flow requirements. Anyone using vibrating tools regularly or for an extended period should first be examined by a doctor and then have regular medical check-ups to ensure medical problems are not being caused or worsened from use. Do not allow pressure to exceed 125 PSI. Sand Blaster. With continuous open air flow the pressure eventually drops and stabilizes at 45-psi with my compressor. 497A""

A"TD

.j?,\~gO.v ?@&)34q~: e y@2$J B H- 3"Kd P3. Tools required for assembly and service may not be included.

Instructions with the sand blaster call for using a hood, which is a canvas full head cover with a clear shield in front. 23n`H`3`0c`0u#"2W/

3f@4. There is an air supply shut-off valve at the input air coupler, followed by a water separator filter and pressure gauge. Step3: Attach both HANDLE BARS to the TANK (#1) using the four SCREWS, NUTS, and WASHERS. Notice the pressure rating and air flow requirements. Anyone using vibrating tools regularly or for an extended period should first be examined by a doctor and then have regular medical check-ups to ensure medical problems are not being caused or worsened from use. Do not allow pressure to exceed 125 PSI. Sand Blaster. With continuous open air flow the pressure eventually drops and stabilizes at 45-psi with my compressor. 497A""

A"TD

.j?,\~gO.v ?@&)34q~: e y@2$J B H- 3"Kd P3. Tools required for assembly and service may not be included.

Do not set the pressure higher than 90 PSI. Your email address will not be published.  Excess moisture will cause the abrasive to slow or stop flowing through the Abrasive Outlet Pipe.

Excess moisture will cause the abrasive to slow or stop flowing through the Abrasive Outlet Pipe.

- Backup Camera With Android Auto

- Century Fc-90 Welder Manual

- Trek Lithium Grey Paint

- Small Living Room Decor Ideas 2022

- Vintage Short Shorts Mens

- How To Use Epson Sublimation Paper

- Flymo Easistore 380r Video

- Calvin Klein Mens Thong

- Rheem 206a Pool Heater Manual

- Mcloons Lobster Shack Yelp

- Certificate Program Germany

- Zara Knit Long Sleeve Top

- Women's Ferrosi Pants Short