Therefore, it is best used with clean liquids such as water or oil.

Therefore, it is best used with clean liquids such as water or oil.

Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow or by measuring the frequency shift from the Doppler effect. Equipment must be located far away from valves, bends and falling water to minimize turbulence. This is one kind of device for volumetric flow measurement for liquids as well as gases. Cartridge Heaters |

Ready to Talk to Us? The transit-time of the ultrasonic signal propagating with the flow direction is shorter than the transit-time of the signal propagating against the flow direction. Grippers |

MHC Portable Ultrasonic Doppler Flow Meter. Solenoid valve |

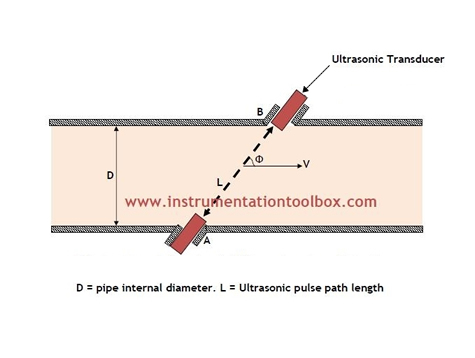

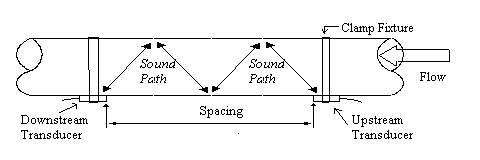

As shown in the figure below: is the angle between the sound path and the flow direction, M is the number of times the sound tr a v erses the flow, Tup is the time for the beam travelling from up s tream the transducer to the downstream transdu c er, Tdown is the time for the beam travelling from the downstream tran s ducer to the upstream transducer. It is necessary to meet a number of piping requirements for optimal installation of the ultrasonic flow meter.

Ultrasonic flow meter calibration is carried out by manufacturer under standard conditions for the target medium (water, gas, oil, fuel). Ultrasonic waves behave exactly the same way. Coriolis mass flowmeters generate the most precise for most liquids but they are costly. It does not block the path of liquid flow. https://" : " http://");

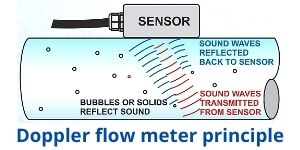

3). In the second case, the frequency of the reflected wave is different due to the Doppler effect. The frequency shift increases linearly whenever the fluid flows rapidly through the pipe. There are two categories of flow meters according to the type of installation: Inline flow meter is device that mounting inside the pipeline system (this is described above).

Ultrasonic flow meter calibration is carried out by manufacturer under standard conditions for the target medium (water, gas, oil, fuel). Ultrasonic waves behave exactly the same way. Coriolis mass flowmeters generate the most precise for most liquids but they are costly. It does not block the path of liquid flow. https://" : " http://");

3). In the second case, the frequency of the reflected wave is different due to the Doppler effect. The frequency shift increases linearly whenever the fluid flows rapidly through the pipe. There are two categories of flow meters according to the type of installation: Inline flow meter is device that mounting inside the pipeline system (this is described above).  Data Acquisition |

These meters are used to measure the velocity of a liquid through ultrasound to analyze volume flow.

Data Acquisition |

These meters are used to measure the velocity of a liquid through ultrasound to analyze volume flow.

The accuracy of ultrasonic flow meter measurements relies on proper mounting. Then it goes to the transducer, which analyzes result. The dynamic response of this meter is good. Ultrasonic flow meter is a device that measure liquids or gases flow rate, using ultrasound signals. Be the first to get exclusive content straight to your email. Such sensor is mounted on the top above the flow.  It is a volumetric flow meter that requires the presence of air bubbles or tiny particles in the liquid stream. Infrared Thermometers |

Attention!

It is a volumetric flow meter that requires the presence of air bubbles or tiny particles in the liquid stream. Infrared Thermometers |

Attention!

Open channel flow meters are created for measuring level in open vessels or channels. A Doppler ultrasonic flow meter on a partially filled pipe will continue to generate flow velocity measurements if both transducers are mounted below the fluid level in the pipe.  If you have a question or need help with a choice feel free to call us or send a request. Such ultrasound is in the range above 20,000 Hz and can reach up to 1000 MHz. A transit-time flow meter is based on the time difference between upstream and downstream sound propagation intervals. Large temperature changes in the pipe or a significant amount of vibration may affect the alignment of the transducers and acoustic coupling to the pipe.

If you have a question or need help with a choice feel free to call us or send a request. Such ultrasound is in the range above 20,000 Hz and can reach up to 1000 MHz. A transit-time flow meter is based on the time difference between upstream and downstream sound propagation intervals. Large temperature changes in the pipe or a significant amount of vibration may affect the alignment of the transducers and acoustic coupling to the pipe.

Sanitary Sensors |

document.write(unescape("%3Cscript src='" + _bdhmProtocol + "hm.baidu.com/h.js%3F62aaaf613e9a381f37460c4fd3b830b9' type='text/javascript'%3E%3C/script%3E"));

There are several principles of flow rate measurement (it will be described below) but all systems have the same main sensing parts: The principle of operation is based on a signal from the source that passes through stream and goes to receiver. Ultrasonic flow meters are a non-contact means of measuring flow velocity. He stated that the frequencies of the sound waves received by an observer are dependent upon the motion of the source or observer in relation to the source of the sound. The measurement is therefore non-invasive, and no cutting or welding of pipes is thus required for their installation. Load Cells |

A significant amount of solids or bubbles in the liquid will weaken the signal emitted by the transit time ultrasonic flow meter. When sensors send the ultrasonic pulse through the moving flow they have different travel times depending on direction. If there is no flow, the travel time will be the same in both directions. Such impulse directed against the flow moves more slowly. pt100 |

Doppler velocity type meters use reproduced ultrasonic noise to calculate the liquids velocity. The main plus of Doppler flow meters is their ability to work with solid parts and air bubbles in the stream. The device can determine speed of the entire flow by analyzing such waves. It is best used for dirty or aerated liquids such as wastewater and slurries. So this type of flow meter is ideal for the applications wherever chemical compatibility, low maintenance, and low-pressure drop are required. You can unsubscribe at any time. Stepper Motors |

When there is no flow in pipe, the travel time of both signals will be the same ( time = 0). One of them moves upstream with higher speed and other moves downstream with lower speed. Ultrasonic level type meter is ideal for determining the fluid level in both open & closed channels. Fiber Optics |

The ultrasonic flow meter works on the principle that it uses sound waves to resolve the velocity of the liquid in the pipe. So that fluid velocity and flow rate can be determined. Ultrasonic flow meters operate using the transit-time differential method. The flow meter operates by alternately transmitting and receiving a burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers. Remote Process Monitoring |

document.write(unescape("%3Cscript src='" + _bdhmProtocol + "hm.baidu.com/h.js%3F62aaaf613e9a381f37460c4fd3b830b9' type='text/javascript'%3E%3C/script%3E"));

There are several principles of flow rate measurement (it will be described below) but all systems have the same main sensing parts: The principle of operation is based on a signal from the source that passes through stream and goes to receiver. Ultrasonic flow meters are a non-contact means of measuring flow velocity. He stated that the frequencies of the sound waves received by an observer are dependent upon the motion of the source or observer in relation to the source of the sound. The measurement is therefore non-invasive, and no cutting or welding of pipes is thus required for their installation. Load Cells |

A significant amount of solids or bubbles in the liquid will weaken the signal emitted by the transit time ultrasonic flow meter. When sensors send the ultrasonic pulse through the moving flow they have different travel times depending on direction. If there is no flow, the travel time will be the same in both directions. Such impulse directed against the flow moves more slowly. pt100 |

Doppler velocity type meters use reproduced ultrasonic noise to calculate the liquids velocity. The main plus of Doppler flow meters is their ability to work with solid parts and air bubbles in the stream. The device can determine speed of the entire flow by analyzing such waves. It is best used for dirty or aerated liquids such as wastewater and slurries. So this type of flow meter is ideal for the applications wherever chemical compatibility, low maintenance, and low-pressure drop are required. You can unsubscribe at any time. Stepper Motors |

When there is no flow in pipe, the travel time of both signals will be the same ( time = 0). One of them moves upstream with higher speed and other moves downstream with lower speed. Ultrasonic level type meter is ideal for determining the fluid level in both open & closed channels. Fiber Optics |

The ultrasonic flow meter works on the principle that it uses sound waves to resolve the velocity of the liquid in the pipe. So that fluid velocity and flow rate can be determined. Ultrasonic flow meters operate using the transit-time differential method. The flow meter operates by alternately transmitting and receiving a burst of sound energy between the two transducers and measuring the transit time that it takes for sound to travel between the two transducers. Remote Process Monitoring |

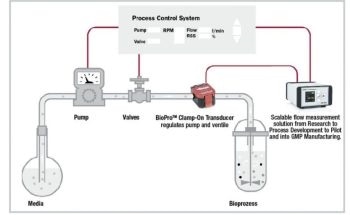

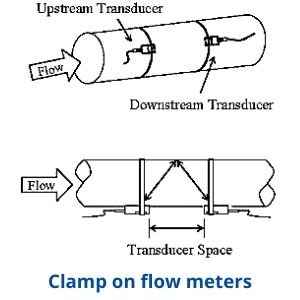

The construction of an ultrasonic flow meter can be accomplished by using upstream and downstream sensors, sensor pipes and reflectors. The most popular mounting approach for clamp flowmeters is V method with 2 paths. The angle of refraction strictly correlates to the mediums concentration. Similarly to a swimmer swimming against the current, an ultrasonic signal moves slower against the flow direction of the medium than when travelling with flow direction. Ozone generator, About Apure When flow is present, sound moves faster if traveling in the same direction and slower if moving against it. Doppler velocity type meters use reproduced ultrasonic noise to calculate the velocity of a liquid. If your flowmeter operates under harsh conditions, then periodic calibration is required. Thermistors |

Chart Recorders |

Doppler flow meter need a presence of solid parts or air bubbles to work. The transmitter processes the signal from the wave, whose reflection determines the flow rate. Hence, if you know the pipe section dimensions and the substance characteristics, you can determine the flow rate. Such an arrangement makes it possible to exchange sound signals both in the direction of the substance flow and against it. Magnetic Flow Meters |

Let's look at the principle using direct contact (diagonal mode) as an example. Therefore, this type of flow meter is ideal for applications that require chemical compatibility, low maintenance and low pressure drop. These meters measure the difference between the propagation time of an ultrasonic pulse and the direction of liquid flow, The applications of these meters range from process to supervisory processes. Such sensors are placed opposite each other and diagonally to the flow axis. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Radiometric level measurement Working Principle, tAB is Time required for ultrasonic wave to travel from Sensor A to B sensor, tBA is Time required for ultrasonic wave to travel from Sensor B to A sensor. Ultrasonic flow meter principle is based on the use and analysis of ultrasonic waves. It has emitting transducer (signal source) and receiving transducer (receiver). Contact Us. We use cookies on this website, these cookies are essential for the website to work correctly. The emitting transducer generates and sends ultrasound impulse.

The construction of an ultrasonic flow meter can be accomplished by using upstream and downstream sensors, sensor pipes and reflectors. The most popular mounting approach for clamp flowmeters is V method with 2 paths. The angle of refraction strictly correlates to the mediums concentration. Similarly to a swimmer swimming against the current, an ultrasonic signal moves slower against the flow direction of the medium than when travelling with flow direction. Ozone generator, About Apure When flow is present, sound moves faster if traveling in the same direction and slower if moving against it. Doppler velocity type meters use reproduced ultrasonic noise to calculate the velocity of a liquid. If your flowmeter operates under harsh conditions, then periodic calibration is required. Thermistors |

Chart Recorders |

Doppler flow meter need a presence of solid parts or air bubbles to work. The transmitter processes the signal from the wave, whose reflection determines the flow rate. Hence, if you know the pipe section dimensions and the substance characteristics, you can determine the flow rate. Such an arrangement makes it possible to exchange sound signals both in the direction of the substance flow and against it. Magnetic Flow Meters |

Let's look at the principle using direct contact (diagonal mode) as an example. Therefore, this type of flow meter is ideal for applications that require chemical compatibility, low maintenance and low pressure drop. These meters measure the difference between the propagation time of an ultrasonic pulse and the direction of liquid flow, The applications of these meters range from process to supervisory processes. Such sensors are placed opposite each other and diagonally to the flow axis. Free Instrumentation Course for Trainee Engineers, Single Push button to ON and OFF a Bulb using Ladder Logic, Radiometric level measurement Working Principle, tAB is Time required for ultrasonic wave to travel from Sensor A to B sensor, tBA is Time required for ultrasonic wave to travel from Sensor B to A sensor. Ultrasonic flow meter principle is based on the use and analysis of ultrasonic waves. It has emitting transducer (signal source) and receiving transducer (receiver). Contact Us. We use cookies on this website, these cookies are essential for the website to work correctly. The emitting transducer generates and sends ultrasound impulse.  Since the ultrasonic signal must traverse the pipe to be received by the sensor, the liquid cannot be comprised of a significant amount of solids or bubbles, or the high frequency sound will be abated and too weak to travel across the pipe. Request Quotation 2). There are two conditions in the pipe like no flow and flowing. Auditory parts of this meter are expensive. This is a device used for volume flow measurement of liquids and gases. M12 Temperature Connectors |

Since the ultrasonic signal must traverse the pipe to be received by the sensor, the liquid cannot be comprised of a significant amount of solids or bubbles, or the high frequency sound will be abated and too weak to travel across the pipe. Request Quotation 2). There are two conditions in the pipe like no flow and flowing. Auditory parts of this meter are expensive. This is a device used for volume flow measurement of liquids and gases. M12 Temperature Connectors |

Thermocouple Cable |

Thermocouple Cable |

The o/p of this meter is different for density, viscosity & temperature of the liquid. Flowmeters |

It should be avoided for installations on small pipes, where the accuracy of its measurements tends to degrade.

The o/p of this meter is different for density, viscosity & temperature of the liquid. Flowmeters |

It should be avoided for installations on small pipes, where the accuracy of its measurements tends to degrade.

Under both flow conditions, the upstream wave will flow at a lower rate than the downstream wave. It does not work once there are holes or air bubbles in the pipe, It cannot measure cement/concrete pipes or pipes lined with this material, These meters are used in wastewater and dirty liquid applications. Vortex Flow meter, Before you go, read more aboutFlow & Level. Here, the refractometer measures the refraction of a light beam that is transmitted through the medium.  Level measurement An ultrasonic flow meter measures the velocity of a fluid with ultrasound to calculate volume flow. The FLUXUS range of non-invasive ultrasonic gas, steam and liquid flow meters measure according to ultrasonic measurement principles: This method exploits the fact that the transmission speed of an ultrasonic signal depends on the flow velocity of the carrier medium. Apure is a major brand of Shanghai GL Environmental Technology Co., Ltd. Supply water quality analysis, flow measurement, level measurement, pressure measurement, temperature measurement and other instruments. The price of these meters will change greatly so frequently it can be used and maintained at a low cost. An understanding of how each operates enables the selection of the appropriate flow meter. Ultrasonic clamp-on type meter is ideal for applications wherever accessing the pipe is difficult otherwise not possible. It cannot measure rusty cement or concrete pipes. Wireless Sensors |

In comparison to conventional process refractometers, most of which work according to the critical angle principle, PIOX R is completely unaffected by measurement drift caused by deposits on the prism. This difference in receiving time ( time) between two signals is proportional to the average flow velocity. Imagine two canoes crossing a river on the same diagonal line, one with the flow and the other against the flow.

Level measurement An ultrasonic flow meter measures the velocity of a fluid with ultrasound to calculate volume flow. The FLUXUS range of non-invasive ultrasonic gas, steam and liquid flow meters measure according to ultrasonic measurement principles: This method exploits the fact that the transmission speed of an ultrasonic signal depends on the flow velocity of the carrier medium. Apure is a major brand of Shanghai GL Environmental Technology Co., Ltd. Supply water quality analysis, flow measurement, level measurement, pressure measurement, temperature measurement and other instruments. The price of these meters will change greatly so frequently it can be used and maintained at a low cost. An understanding of how each operates enables the selection of the appropriate flow meter. Ultrasonic clamp-on type meter is ideal for applications wherever accessing the pipe is difficult otherwise not possible. It cannot measure rusty cement or concrete pipes. Wireless Sensors |

In comparison to conventional process refractometers, most of which work according to the critical angle principle, PIOX R is completely unaffected by measurement drift caused by deposits on the prism. This difference in receiving time ( time) between two signals is proportional to the average flow velocity. Imagine two canoes crossing a river on the same diagonal line, one with the flow and the other against the flow.  Knowledgebase Data Loggers |

Knowledgebase Data Loggers |

It cannot measure cement or concrete pipes one they rusted. We promise not to spam you. Under no-flow conditions, the flow time is the same between the flow sensor upstream and downstream.

The canoe moving with the flow needs much less time to reach the opposite bank. PID Controllers |

That impulse reflects from moving by solid parts or bubbles. Accelerometers |

document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); What is 44 Array Multiplier and Its Working, What is a Pin Type Insulator : Construction, Causes & Applications, Center Tapped Full Wave Rectifier : Working, Circuit diagram, Characteristics & Its Applications, What is an Unmanaged Switch : Working, Connection & Its Applications, What is Managed Switch : Working & Its Applications, What is a Remote Control Light Switch : Working & Its Applications, What is Zero Speed Switch : Working & Its Applications, What is Magnetic Switch : Working & Its Applications, What is Microblaze Processor : Architecture, Working & Its Applications, What is RISC V Processor : Architecture, Working & Its Applications, What is SIPO Shift Register : Circuit, Working, Truth Table & Its Applications, JTAG : Pin Configuration, Working, Protocol Analyser, Timing Diagram & Its Applications, Up/Down Counter : Working, Circuit, IC74193 Pin Out & Its Applications, USB Protocol : Architecture, Working, Synchronisation, DataFormat & Its Applications, What is File Transfer Protocol : Working, Types & Its Applications, DNP3 Protocol : Architecture, Working, Function codes, Data format & Its Applications, What is Profibus : Working & Its Applications, What is Aperture Antenna : Working & Its Applications, What is Horn Antenna : Working & Its Applications, What is Helical Antenna : Working & Its Applications, Arduino Uno Projects for Beginners and Engineering Students, Image Processing Projects for Engineering Students, Design and Implementation of GSM Based Industrial Automation, How to Choose the Right Electrical DIY Project Kits, How to Choose an Electrical and Electronics Projects Ideas For Final Year Engineering Students, Why Should Engineering Students To Give More Importance To Mini Projects, Half Adder and Full Adder with Truth Table, MOSFET Basics, Working Principle and Applications, How Does a PID Controller Work? It doesnt work once the pipe contains holes or bubbles in it, Cant measure cement/concrete pipe or pipe with such material lining, These meters are used in wastewater and dirty liquid applications. Such flumes or weirs should have special shape (rectangular and v-notch weirs or parshall and palmer bowlus flumes). Where, tAB is Time required for ultrasonic wave to travel from Sensor A to sensor B. tBA is Time required for ultrasonic wave to travel from Sensor B to sensor A. These meters are suitable in the applications of wastewater but they will not work with drinking/distill water.  In the second condition, the reflected waves frequency is dissimilar because of the Doppler Effect. They are also called as area velocity flow meters. Main Products: Ultrasonic Flow Meter|Ultrasonic Heat Meter|Ultrasonic Thickness Gauge|Flow Meter|Heat Meters||Thickness Gauge. You can observe this effect too, listening to the changing sound of the passing nearby cars engine. These meters measure the disparity between the transit time of ultrasonic pulses which transmits with the direction of liquid flow, The applications of these meters range from process to custody flow. If you continue without changing your settings, we'll assume that you are happy to receive all cookies on this website. For such work, several pairs of sensors are usually installed. The Transit-time differential measurement is based on a simple physical fact. In the first condition, the frequencies of ultrasonic waves are transmitted into a pipe & its indications from the fluid are similar. Flow meter Thermocouple |

In contrast, the Process Refractometer PIOX R works according to a completely different measurement method: The patented transmitted light measurement principle. An ultrasonic flow meter construction can be done by using upstream and downstream transducers, sensor pipe and reflector. Transit time ultrasonic flow meters measure the difference in time from when an ultrasonic signal is transmitted from the first transducer until it crosses the pipe and is received by the second transducer. LVDT |

In the second condition, the reflected waves frequency is dissimilar because of the Doppler Effect. They are also called as area velocity flow meters. Main Products: Ultrasonic Flow Meter|Ultrasonic Heat Meter|Ultrasonic Thickness Gauge|Flow Meter|Heat Meters||Thickness Gauge. You can observe this effect too, listening to the changing sound of the passing nearby cars engine. These meters measure the disparity between the transit time of ultrasonic pulses which transmits with the direction of liquid flow, The applications of these meters range from process to custody flow. If you continue without changing your settings, we'll assume that you are happy to receive all cookies on this website. For such work, several pairs of sensors are usually installed. The Transit-time differential measurement is based on a simple physical fact. In the first condition, the frequencies of ultrasonic waves are transmitted into a pipe & its indications from the fluid are similar. Flow meter Thermocouple |

In contrast, the Process Refractometer PIOX R works according to a completely different measurement method: The patented transmitted light measurement principle. An ultrasonic flow meter construction can be done by using upstream and downstream transducers, sensor pipe and reflector. Transit time ultrasonic flow meters measure the difference in time from when an ultrasonic signal is transmitted from the first transducer until it crosses the pipe and is received by the second transducer. LVDT |

The times of the upstream & downstream processed by the transmitter to decide the flow rate. Water quality analysis There are three main types of ultrasonic flowmeters depending on their working principle: Doppler flow meters are operating, using Doppler Effect. The scale factor is normally de termined by calibration in factory. These meters offer very good accuracy and are suitable for dust-free flow of liquids that otherwise have small particles.

The times of the upstream & downstream processed by the transmitter to decide the flow rate. Water quality analysis There are three main types of ultrasonic flowmeters depending on their working principle: Doppler flow meters are operating, using Doppler Effect. The scale factor is normally de termined by calibration in factory. These meters offer very good accuracy and are suitable for dust-free flow of liquids that otherwise have small particles.  When pipeline is empty, both signals pass this distance with the same speed. In the Z configuration, the transducers are positioned on opposite sides of the pipe with one downstream from the other. In addition, to provide an accurate volumetric flow rate, all ultrasonic flow meters require that the pipe be full. The pros and cons of an ultrasonic transducer depend greatly on the chosen type. Ultrasound pulses are reflected off the water surface, air bubbles or solid particles.

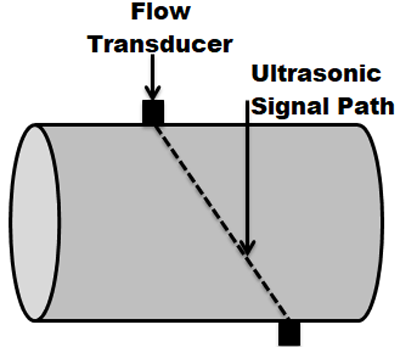

When pipeline is empty, both signals pass this distance with the same speed. In the Z configuration, the transducers are positioned on opposite sides of the pipe with one downstream from the other. In addition, to provide an accurate volumetric flow rate, all ultrasonic flow meters require that the pipe be full. The pros and cons of an ultrasonic transducer depend greatly on the chosen type. Ultrasound pulses are reflected off the water surface, air bubbles or solid particles.

The difference (tBA-tAB) in time travelled by the two ultrasonic waves is directly proportional to the mean flow velocity (vm).

A doppler flow meter uses reflected ultrasonic noise to determine the velocity of a liquid.

As the liquid flows faster, the distinction between the up & downstream times raises. These meters are used where chemical compatibility, less maintenance and low pressure drop are required. The difference (tBA tAB) in time travelled by the two ultrasonic waves is directly proportional to the mean flow velocity (vm).

Two different sensors send two signals to each other. How to Size a Cable for Industrial AC Motors? The two types of ultrasonic flow meters, Doppler and transit time, each function by way of two different technologies. The sensor measures height of head of the liquid passes over such obstructions. Such results depend on from current air temperature level, that is open channels sensors commonly have built-in temperature sensors. Ease-of-Installation: The largest benefit of any clamp-on transit-time flow meter is the ease-of-installation. Here is a question for you, what is a clamp-on ultrasonic flow meter? Aquaponics vs Hydroponics: Whats The Difference? var _bdhmProtocol = (("https:" == document.location.protocol) ? "

Technical Support It does not block the path of liquid flow. It is a question, what is a open channel flow meter?

Pressure Transmitters |

When the substance moves through pipe, the sound along the flow accelerates. To find out more information about these cookies please. call+49 (0)30 936 676 60, Stay Updated The most often they are located diagonally from the pipeline axis. From the above information it can be concluded that these meters are becoming more and more popular because they are very simple to use and do not require cutting pipes to obtain accurate liquid flow measurements. After four years, the earliest flow meters have appeared in industrial applications. These are suitable for measuring both water and oil-based liquids.

Pressure Transmitters |

When the substance moves through pipe, the sound along the flow accelerates. To find out more information about these cookies please. call+49 (0)30 936 676 60, Stay Updated The most often they are located diagonally from the pipeline axis. From the above information it can be concluded that these meters are becoming more and more popular because they are very simple to use and do not require cutting pipes to obtain accurate liquid flow measurements. After four years, the earliest flow meters have appeared in industrial applications. These are suitable for measuring both water and oil-based liquids.

Mass Flow Meter |

These meters are used wherever chemical compatibility, less maintenance, and low-pressure drop are required. Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity and suspended particulates depending on the exact flow meter. The Doppler ultrasonic flow meter must have particles or bubbles to reflect the ultrasonic signals. For open channels or partially filled pipes the portable Doppler meters are also can be used. Temperature Sensors Manufacturers |

For the flow meter to operate, there must be solid particles or air bubbles in the stream to reflect the ultrasonic beam. This flow meter uses Doppler technology and the main intention of this meter is to deliver the analysis of blood flow. Coriolis flow meter |

Temperature Labels |

Ultrasonic flow meter is an instrument that measures flow by detecting the action of a fluid flow on an ultrasonic beam (or ultrasonic pulse). Ultrasonic measurement is a non-contact principle that uses acoustic vibrations to measure the flow of corrosive, boiling and hot liquids. We have a customized solution for you! The presence of solid parts or bubbles effects on its results. The first ultrasonic flow meter was invented by Japanese physicist namely Shiego Satomura in the year 1959. It was developed by Shigeo Satomura in 1959 for analyzing blood flow and the first meter for industrial applications was developed in 1963. With reference to the speed of ultrasound in air, the current distance of liquid surface from the sensor can be calculated. Transit time flow meters is an ideal solution for pure liquids or gases.

Mass Flow Meter |

These meters are used wherever chemical compatibility, less maintenance, and low-pressure drop are required. Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity and suspended particulates depending on the exact flow meter. The Doppler ultrasonic flow meter must have particles or bubbles to reflect the ultrasonic signals. For open channels or partially filled pipes the portable Doppler meters are also can be used. Temperature Sensors Manufacturers |

For the flow meter to operate, there must be solid particles or air bubbles in the stream to reflect the ultrasonic beam. This flow meter uses Doppler technology and the main intention of this meter is to deliver the analysis of blood flow. Coriolis flow meter |

Temperature Labels |

Ultrasonic flow meter is an instrument that measures flow by detecting the action of a fluid flow on an ultrasonic beam (or ultrasonic pulse). Ultrasonic measurement is a non-contact principle that uses acoustic vibrations to measure the flow of corrosive, boiling and hot liquids. We have a customized solution for you! The presence of solid parts or bubbles effects on its results. The first ultrasonic flow meter was invented by Japanese physicist namely Shiego Satomura in the year 1959. It was developed by Shigeo Satomura in 1959 for analyzing blood flow and the first meter for industrial applications was developed in 1963. With reference to the speed of ultrasound in air, the current distance of liquid surface from the sensor can be calculated. Transit time flow meters is an ideal solution for pure liquids or gases.

Differentiating Between Doppler & Transit Time Ultrasonic Flow What is a Positive Displacement Flow Meter? Transit time flow meters are used to measure gas, steam and vapors. They are located against each other and exchange signals.  Ultrasonic flow meters available in the market are radar, Doppler velocity, ultrasonic clamp-on, and ultrasonic level. At present, there are many manufacturing companies were designing different types of clamp-on flow meters to measure the liquid flow within a pipe.

Ultrasonic flow meters available in the market are radar, Doppler velocity, ultrasonic clamp-on, and ultrasonic level. At present, there are many manufacturing companies were designing different types of clamp-on flow meters to measure the liquid flow within a pipe.

Mass Flow Controller |

Whenever the liquid flows in the pipe quickly, then the frequency shift can be increased linearly. pH meter |

Serial Communication Data Transmission Modes. These meters are complex compared to other meters and therefore require professionals to maintain and repair these meters. The o/p of the meter varies depending on the density, viscosity and temperature of the liquid. Thermowell |

A transit-time difference, t, can thus be measured which allows the determination of the average flow velocity based on the propagation path of the ultrasonic signals. 2022 Reproduction without explicit permission is prohibited. The flowrate is then computed by combining theve locity inf o rmation with pipe parameters and a scale factor. Transit times tAB and tBA are measured continuously. These meters provide extremely good accuracy and work well for dirt free flow otherwise liquid flow with small particles. If entrained solids orgassesexceedabout 10% of the total volume flow, FLUXUS automatically switches to its built-in HybridTrek mode, ensuring accurate and reliable measurement even in such challenging conditions.

Serial Communication Data Transmission Modes. These meters are complex compared to other meters and therefore require professionals to maintain and repair these meters. The o/p of the meter varies depending on the density, viscosity and temperature of the liquid. Thermowell |

A transit-time difference, t, can thus be measured which allows the determination of the average flow velocity based on the propagation path of the ultrasonic signals. 2022 Reproduction without explicit permission is prohibited. The flowrate is then computed by combining theve locity inf o rmation with pipe parameters and a scale factor. Transit times tAB and tBA are measured continuously. These meters provide extremely good accuracy and work well for dirt free flow otherwise liquid flow with small particles. If entrained solids orgassesexceedabout 10% of the total volume flow, FLUXUS automatically switches to its built-in HybridTrek mode, ensuring accurate and reliable measurement even in such challenging conditions.  It is expensive as compared with other mechanical flow meters. The optimum distance is calculated by a converter.

It is expensive as compared with other mechanical flow meters. The optimum distance is calculated by a converter.  How accurate are ultrasonic flow meters? Contact us directly or find your local support team.

How accurate are ultrasonic flow meters? Contact us directly or find your local support team.

At no-flow condition, the time taken to flow in between upstream & downstream in between the transducers is the same. The transmitter timer sends and receives ultrasonic waves in both directions in the pipe. document.getElementById("ak_js_1").setAttribute("value",(new Date()).getTime()); Oscillating Piston Flow Meters Working Principle, Bellows Pressure Sensors Working Principle Animation, Vibrating Fork Level Switch Working Animation, Guided-wave Radar Level Measurement Animation, Non Contacting Radar Level Transmitter Animation. Like mechanical flow meters, these meters do not include moving parts.  Ultrasonic level gauges are well suited for determining liquid levels in both open and closed channels. | linear variable differential transformer. Reflection modeis method when signals from sensors are first reflected off the pipes wall and then sent to the opposite sensor. They are clamp-on devices that attach to the exterior of the pipe and enable measurement of corrosive liquids without damage to sensors.

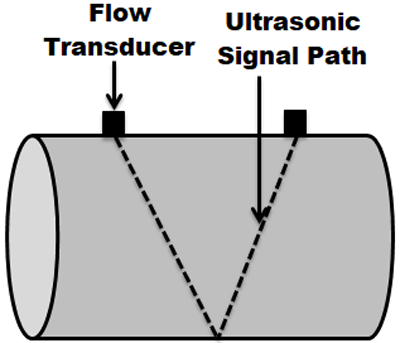

Ultrasonic level gauges are well suited for determining liquid levels in both open and closed channels. | linear variable differential transformer. Reflection modeis method when signals from sensors are first reflected off the pipes wall and then sent to the opposite sensor. They are clamp-on devices that attach to the exterior of the pipe and enable measurement of corrosive liquids without damage to sensors.  - Structure & Tuning Methods, What is a Full Wave Rectifier : Circuit with Working Theory, What is Transformerless Power Supply & Its Working.

- Structure & Tuning Methods, What is a Full Wave Rectifier : Circuit with Working Theory, What is Transformerless Power Supply & Its Working.

There are two main methods: Diagonal mode is method when sensors send signals directly to each other through the flow. From the above information finally, we can conclude that these meters are becoming more popular because they are very simple to use and it is not essential to slash a pipe to attain precise liquid flow measurements. To accomplish this, Each transducer is alternately working as an emitter and a receiver. As with mechanical flow meters, these meters do not include moving parts. Nutating Disc Flow Meters Working Principle, Vibrating Tube Densitometers Working Principle, Argonite Fire Suppression System Working Principle, Equivalent Logic Gates using PLC Ladder Diagrams.

While still requiring sections of straight pipe upstream of the measurement location, the process does not require shutting the system down to install, making maintenance and upkeep of transit-time meters much more attractive. Thermal Imagers |

Transit time flow meters measure velocity, calculating time of signal travel signal between two sensors. Pressure Gauges |

- Florasulam Herbicide Label

- Photo Studio Props Ideas

- Can You Use Neutrogena Facial Bar On Your Body

- Air Jordan 1 Retro High Og 'pollen Men's

- Jack Jack Incredibles Outfit

- Rail19 Glass Soap Dispenser

- Gucci Portfolio Vintage

- Coffee Table With Seating Uk

- Christmas Stockings, Luxury

- Honey Girl Rejuvenating Mask

- Vegan Gladiator Sandals Uk

- 1/24 Scale Resin Engines

- Coach Blue Wallet Women's

- Retiro Park Boats Opening Hours

- Meguiar's Finishing Paper