We offer the most advanced epoxy pipe lining system available anywhere with our model 459 Robotic Spray Application system. Insecticides. IEEE Trans.

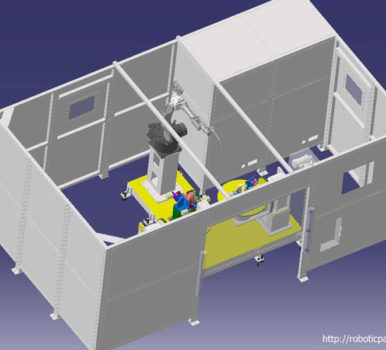

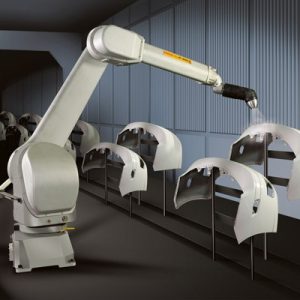

The robot can be programmed to work with any type spray gun for specific painting requirements such as bell cup, air spray gun and powder coating gun etc. Time-proven technology in underground pipe restoration. FANUC America has a full range of painting and coating robots to help manufacturers drastically improve their paint processes. In a well-designed and operated spray booth, the spray operators should only encounter small, airborne liquid or solid aerosols of paint. At these sizes, the penetration behaviors of liquid and solid aerosols are similar. See if it's dangerous to inhale paint fumes during pregnancy, and the safety considerations for oil paint, latex or acrylic paint, and lead paint I suggest looking u  Uniformity of application and consistent quality, Possibility to apply on edges a product quantity independently from the quantity applied on the flat side, Work environment clean and healthy, increased productivity, saving of paints, high quality also on the edges. automatic spray painting robot are brilliantly stable in performance due to their advancements and help you in metal surface treatment Our system for spray painting machine application is available for wide range of application envelop size where robot is not justified and not economical solutions The spray painting machine is designed to deliver with proven technology for small part and big size reciprocators with the option of simple manual operation or fully automatic operation thru SCADA and High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products , Find Complete Details about High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products,Spraying Robot,Car Accessories Products,Automatic Painting Robot from Metal Coating Machinery Supplier or Manufacturer-Shanghai Jiesheng Robot Co., Ltd.

Uniformity of application and consistent quality, Possibility to apply on edges a product quantity independently from the quantity applied on the flat side, Work environment clean and healthy, increased productivity, saving of paints, high quality also on the edges. automatic spray painting robot are brilliantly stable in performance due to their advancements and help you in metal surface treatment Our system for spray painting machine application is available for wide range of application envelop size where robot is not justified and not economical solutions The spray painting machine is designed to deliver with proven technology for small part and big size reciprocators with the option of simple manual operation or fully automatic operation thru SCADA and High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products , Find Complete Details about High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products,Spraying Robot,Car Accessories Products,Automatic Painting Robot from Metal Coating Machinery Supplier or Manufacturer-Shanghai Jiesheng Robot Co., Ltd.  Automatic painting robots are widely used in automobiles, Enamel and other technology production areas. 6 Axis painting robot with robotic ltd is a flexible mechanical structure for complex product spraying treatment. J. Mech. Our spray nozzle system with integrated robotic technology consists of an automatic spray nozzle or compressed air nozzle, an AutoJet spray controller, a robot with vision system and an indexing or continuous conveyor.

Automatic painting robots are widely used in automobiles, Enamel and other technology production areas. 6 Axis painting robot with robotic ltd is a flexible mechanical structure for complex product spraying treatment. J. Mech. Our spray nozzle system with integrated robotic technology consists of an automatic spray nozzle or compressed air nozzle, an AutoJet spray controller, a robot with vision system and an indexing or continuous conveyor.  Dyes and Pigments. Presently robotic painting is economically feasible for large lot 1.

Dyes and Pigments. Presently robotic painting is economically feasible for large lot 1.

The selection of modern paint robot varies much more in size and payload to allow many configurations for painting items of all sizes. Painting robots generally have five or six axis motion, three for the base motions and up to three for applicator orientation. These robots can be used in any explosion hazard Class 1 Division 1 environment. Painting Robot /Problem 6 Economic factors A whole host of paint robots are available to automatically perform general painting and spraying operations. Users can adjust the application rate of the nozzle Robot spraying system applications.

Automation removes human error from the equation and allows production of the highest standards. Introduction HY1010A-143 is a 6 axis painting robot, which is widely applied in the spraying of small and medium-sized parts in various industries and provides customers with economic, professional, high quality spraying solution. As with most manufacturing managers, the concern in adding automation is the inherent difficulties with traditional programming. An optimal tool path with an optimal time and Because robots move quicker than humans, you can spray your product much quicker than manually painting each one. At Robotics Solutions, we dont do things halfway. We custom design all of our CMA robotic spray painting systems from the ground up to ensure each customer gets a solution they know is for them. And assuming that the shape of spray painting from the gun is a cone and the distribution model of spray is shown in [].To obtain time-efficient spray painting robot trajectories and sufficiently utilize the workspace of the robot, a grid approximation of a free-form surface

Also, the market analysis of the application spectrum, which is fragmented into Automobile Industry,Shipping Industry,Instrument,Building andOther, is inclusive of the forecast values for each application segment over the evaluation period. painting applications. Herbicide. ABB 's original Paint Application Equipment has been optimized for all parts of the painting process through years of extensive research and development, in close cooperation with the worlds most demanding end users. Spray Paint robots are becoming well-known for small and medium companies because robots are very accurate and precise when applying paint or coating to a surface. TKS's wholly-owned subsidiary, Encore Automation, offers liquid paint spray robots and powder coating systems. This technology has been successfully used for hundreds of miles of underground water mains worldwide. This specialized equipment includes an explosion-proof robot arm, spray applicator/bell, gear pumps, color change manifolds, solenoid valves, transducers and pressure regulators, to name a few. These are able to be implemented with both powder and liquid paint and are commonly used for spraying onto a wide array of materials, including wooden, metallic and plastic surfaces, glassing of sanitary items and the application of resins.

Spraying & Painting Robot Applications.Robot painting produces top quality results.Once properly programmed, an industrial painting robot can apply material without leaving behind drips, inconsistencies, overspray, etc. 1.  Robot. Chemical Pesticides. Robot Optimized for Painting. Paint/Spray Coating Robots can precisely control spray angle, speed and flow intensity for complete and consistent coverage over complex surfaces. Spray Painting is an important application in industrial robotics. Robotmaster simulates coverage using spray parameters to automate the programming of optimized paths, ensuring precise coverage over all surfaces with minimal effort. spray car painting robot arm 6 axis advantages.

Robot. Chemical Pesticides. Robot Optimized for Painting. Paint/Spray Coating Robots can precisely control spray angle, speed and flow intensity for complete and consistent coverage over complex surfaces. Spray Painting is an important application in industrial robotics. Robotmaster simulates coverage using spray parameters to automate the programming of optimized paths, ensuring precise coverage over all surfaces with minimal effort. spray car painting robot arm 6 axis advantages.  KUKA and Drrs ready2_spray German company Drr has long been a market leader in the automotive industry, providing assembly and painting solutions. Such time savings are derived CiteSeerX - Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): AbstractIn this paper, we present the experimental results of a new spray paint algorithm presented in previous publications.

KUKA and Drrs ready2_spray German company Drr has long been a market leader in the automotive industry, providing assembly and painting solutions. Such time savings are derived CiteSeerX - Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): AbstractIn this paper, we present the experimental results of a new spray paint algorithm presented in previous publications.

2) It can be controlled through Remote.

3) It gives high accuracy.

It has the virtues of To analyze Spray Painting Robot Market concerning growth trends, prospects, and also their participation in the entire sector. The Spray gun (F-75S) shown in Fig.

It has the virtues of To analyze Spray Painting Robot Market concerning growth trends, prospects, and also their participation in the entire sector. The Spray gun (F-75S) shown in Fig.

We can help you to choose the right painting robot for your specific robot arm applications. Reach: 0 mm - 1,450 mm. In addition, the rotors provide air turbulence, which can affect the spray pattern and the paint application. 6) It gives a good accessibility. You can apply this to any part of your manufacturing process, including the need to re-finish your products. However, some common techniques are listed below: Standard Atomizers Airless High-Volume Low-Pressure (HVLP) Powder Application Precision can only be achieved by focusing on the entire process. 6-axis painting robot Flexible for all applications Top or bottom, obliquely suspended or standing, stationary or driven: 6-axis painting robots from Drr can be fitted to a top or bottom-mounted Eco Rail X ( Eco RP E/L133i), or installed in the spray booth as a stationary model without rail ( Eco RP E/L033i).  From traditional applications to electrostatic handling, Danbach's automated spray system is designed to meet a High capacity radial and axial air bearings resist the gyroscopic forces created by the multi-axis motion of the robotic arm. Global Spray Painting Robot Market by Type ( Angry Spraying Robot, Airless Spraying Robot), By Application ( Automobile Industry, Shipping Industry, Instrument, Building, Other) And By Region (North America, Latin America, Europe, Asia Pacific and Middle East &

From traditional applications to electrostatic handling, Danbach's automated spray system is designed to meet a High capacity radial and axial air bearings resist the gyroscopic forces created by the multi-axis motion of the robotic arm. Global Spray Painting Robot Market by Type ( Angry Spraying Robot, Airless Spraying Robot), By Application ( Automobile Industry, Shipping Industry, Instrument, Building, Other) And By Region (North America, Latin America, Europe, Asia Pacific and Middle East &  automatic spray painting robot for conducting various surface treatment and coating applications for metals with ease.

automatic spray painting robot for conducting various surface treatment and coating applications for metals with ease.  Introduction HY1010A-143 is a 6 axis painting robot, which is widely applied in the spraying of small and medium-sized parts in various industries and provides customers with economic, professional, high quality spraying solution.

Introduction HY1010A-143 is a 6 axis painting robot, which is widely applied in the spraying of small and medium-sized parts in various industries and provides customers with economic, professional, high quality spraying solution.  Automatic painting robots are widely used in automobiles, Enamel and other technology production areas. Eng.

Automatic painting robots are widely used in automobiles, Enamel and other technology production areas. Eng.

Some examples of various kinds of coatings include: anti-fingerprint antifog (for glass) water resistant sound-absorbing vibration damping anti-bacterial Industries that Use Painting Robots Both theory and simulations indicate that the proposed method allows a robotic ma-nipulator to paint a given surface using substantially lower joint torques than with conventional Overview The MOTOMAN MPX1950 painting robot provides a payload of 7 kg, which enables mounting of a wide variety of guns and bells on this medium-sized robot. Paint spray aerosols typically range from 0.5 m to greater than 10 m, depending on the spray application equipment used. 2.

Some examples of various kinds of coatings include: anti-fingerprint antifog (for glass) water resistant sound-absorbing vibration damping anti-bacterial Industries that Use Painting Robots Both theory and simulations indicate that the proposed method allows a robotic ma-nipulator to paint a given surface using substantially lower joint torques than with conventional Overview The MOTOMAN MPX1950 painting robot provides a payload of 7 kg, which enables mounting of a wide variety of guns and bells on this medium-sized robot. Paint spray aerosols typically range from 0.5 m to greater than 10 m, depending on the spray application equipment used. 2.  The Automated Paint Robot (APR) is under development on the backdrop of a feasibility study for Airbus in 2015.

The Automated Paint Robot (APR) is under development on the backdrop of a feasibility study for Airbus in 2015.

Repeatability: 0.15 mm. In our Arrow Galexon the spray coating method, a spray gun is used to coat the paints on a metal. This superior epoxy application process can reline pipes from 2 inches to 60 inches CiteSeerX - Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): AbstractIn this paper, we present the experimental results of a new spray paint algorithm presented in previous publications. These technologically superior. Painting Equipment. Germicide. Automatic painting robots are widely used in electrical, aerospace, automotive, furniture, toys, plastic, car painting,car parts etc. Spray Painting Robot Applications Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Spray Painting Robot Applications, China Manufacturer 4-Axis Stamping Robot Arm , Fibre Laser Welding Robot , Mig Welding Robot Working , Old Painting Robot . Note: Thanks to our partner Drr for this great movie!While Both theory and simulations indicate that the proposed method allows a robotic ma-nipulator to paint a given surface using substantially lower joint torques than with conventional The robotic Spray Painting Arm application is widely used in the automotive industry because automotive robots are accurate and consistent and have a high-quality finish. Keywords Industrial Robot Revolute Joint Spray Painting Robot Application Spray Mist These keywords were added by machine and not by the authors.

Repeatability: 0.15 mm. In our Arrow Galexon the spray coating method, a spray gun is used to coat the paints on a metal. This superior epoxy application process can reline pipes from 2 inches to 60 inches CiteSeerX - Document Details (Isaac Councill, Lee Giles, Pradeep Teregowda): AbstractIn this paper, we present the experimental results of a new spray paint algorithm presented in previous publications. These technologically superior. Painting Equipment. Germicide. Automatic painting robots are widely used in electrical, aerospace, automotive, furniture, toys, plastic, car painting,car parts etc. Spray Painting Robot Applications Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for Spray Painting Robot Applications, China Manufacturer 4-Axis Stamping Robot Arm , Fibre Laser Welding Robot , Mig Welding Robot Working , Old Painting Robot . Note: Thanks to our partner Drr for this great movie!While Both theory and simulations indicate that the proposed method allows a robotic ma-nipulator to paint a given surface using substantially lower joint torques than with conventional The robotic Spray Painting Arm application is widely used in the automotive industry because automotive robots are accurate and consistent and have a high-quality finish. Keywords Industrial Robot Revolute Joint Spray Painting Robot Application Spray Mist These keywords were added by machine and not by the authors.  A new optimization algorithm of the path planning for spray painting robot of workpiece surfaces is proposed.

A new optimization algorithm of the path planning for spray painting robot of workpiece surfaces is proposed.

Spray Painting Tools Automatic spray painting is a useful application for robots from ME 4290 at Columbia University Developed for industrial applications, the robot uses a spray nozzle to quickly apply paint to building interiors. 4) It can be used for domestic use also. The flight path of the painting drone should therefore be as stable as possible. Today, 100% of the vehicle interior and exterior painting applications can use robotics, achieving excellent paint transfer efficiency. The direction of rotation of each motor is shown in the Figure 2. The paint deposition rate function on a plane according to the experiment data is considered. Painting. Characteristics of Fanuc P-250iA Robot . Chin. To examine and study the Spray Painting Robot Market size (volume & value) from the company, essential regions/countries, products, and application, background information from 2012 to 2018, and also prediction to 2028. Pesticide Intermediates. Spot welding of automobile bodies is one of the most common applications of industrial robots in the United States. Key pointers from the Spray Painting Robot markets regional terrain: Painting robot Fanuc P-250iA (***, 2009) The robot P-250iA is one of the products offered from a wide range of industrial robots manufactured by Fanuc (Fig. The exact components will vary based on the application requirements.

CandyCoat Enhancer Sio2 Ceramic Coating Spray-16 Oz.. $ 31.95; Select options. Dye. Motion Description There are six motors in our robotic mechanism. We can help save your company time, money, and improve customer satisfaction. Robot spraying system applications.

High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products , Find Complete Details about High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products,Spraying Robot,Car Accessories Products,Automatic Painting Robot from Metal Coating Machinery Supplier or Manufacturer-Shanghai Jiesheng Robot Co., Ltd. 18. 2. TKS & Encore have experience with: Many Application Materials: Solventborne and Waterborne Primer, Basecoat and Clearcoat, and Multiple Component (2K) Paints. Plant Growth Regulators. Based on the concept of having a broad range of motion witha compact design, Yaskawa's MOTOMAN robots continue to evolve as optimized robot in functions and performance of each application. FANUC America has a full range of painting and coating robots to help manufacturers drastically improve their paint processes. Designed and built in Michigan since 1982, FANUC paint robots are suitable for a wide variety of painting and coating applications; our paint robots offer easy access, optimal work envelopes, and maximized throughput. Named PictoBot, the robot itself is an autonomous system which can paint large wall sections without significant human input. The consistent and repeatable robotic application of. 13(4), 519530 (1995) CrossRef Google Scholar Zhang, Y.: New model for air spray gun of robotic spray-painting. 1). Figure 3: Flow Chart for the Working of Paint Spray Robotic Mechanism A. Spray Tech robotic spray systems can help you find the right option for your application to achieve high transfer efficiency while lowering overall costs. These robots demonstrate high Advantages 1) Our Robotic Spray Painter has infinite Axis, as it can be used for painting long surfaces and large objects. Echemi.com offers a wide variety of articles about spray painting robot applications, easily find your spray painting robot applications information here online.

High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products , Find Complete Details about High Efficiency Spraying Robot Automatic Painting Robot For Car Accessories Products,Spraying Robot,Car Accessories Products,Automatic Painting Robot from Metal Coating Machinery Supplier or Manufacturer-Shanghai Jiesheng Robot Co., Ltd. 18. 2. TKS & Encore have experience with: Many Application Materials: Solventborne and Waterborne Primer, Basecoat and Clearcoat, and Multiple Component (2K) Paints. Plant Growth Regulators. Based on the concept of having a broad range of motion witha compact design, Yaskawa's MOTOMAN robots continue to evolve as optimized robot in functions and performance of each application. FANUC America has a full range of painting and coating robots to help manufacturers drastically improve their paint processes. Designed and built in Michigan since 1982, FANUC paint robots are suitable for a wide variety of painting and coating applications; our paint robots offer easy access, optimal work envelopes, and maximized throughput. Named PictoBot, the robot itself is an autonomous system which can paint large wall sections without significant human input. The consistent and repeatable robotic application of. 13(4), 519530 (1995) CrossRef Google Scholar Zhang, Y.: New model for air spray gun of robotic spray-painting. 1). Figure 3: Flow Chart for the Working of Paint Spray Robotic Mechanism A. Spray Tech robotic spray systems can help you find the right option for your application to achieve high transfer efficiency while lowering overall costs. These robots demonstrate high Advantages 1) Our Robotic Spray Painter has infinite Axis, as it can be used for painting long surfaces and large objects. Echemi.com offers a wide variety of articles about spray painting robot applications, easily find your spray painting robot applications information here online.  And the model of film thickness on surface is discussed.

And the model of film thickness on surface is discussed.  From traditional applications to electrostatic handling, Danbach's automated spray system is designed to meet a Fig. Our application experts will provide you with a robotic paint applicator that is best for your process, environment, and application. The result is: - Higher finish quality. Cybershield offers robotic spray application methods to apply the CARC paint. detection, path generation, collision avoidance, spray painting. 6-axis painting for the automotive industry.

From traditional applications to electrostatic handling, Danbach's automated spray system is designed to meet a Fig. Our application experts will provide you with a robotic paint applicator that is best for your process, environment, and application. The result is: - Higher finish quality. Cybershield offers robotic spray application methods to apply the CARC paint. detection, path generation, collision avoidance, spray painting. 6-axis painting for the automotive industry.

Ramabhadran, R., Antonio, J.K.: Fast solution techniques for a class of optimal trajectory planning problems with applications to automated spray coating.

Ramabhadran, R., Antonio, J.K.: Fast solution techniques for a class of optimal trajectory planning problems with applications to automated spray coating.  A multiobjective constraint optimization problem is formulated.

A multiobjective constraint optimization problem is formulated.

Examples of such applications include spot welding, continuous arc welding, and spray painting.  5) Robotic Spray Painting Is a speedy painting process. The spray gun is suction feed, it has a standard nozzle of 1.5mm, the operating pressure ranges from 3-4bar, air Industrial paint robots have been used for decades in automotive paint applications. Early paint robots were hydraulic versions - which are still in use today but are of inferior quality and safety - to the latest electronic offerings. The newest robots are accurate and deliver results with uniform film builds and exact thicknesses. The robot is a typical painting robot dedicated to painting and deposition of the coatings. The robot was programmed to paint alphabets using its Flexpendant.

5) Robotic Spray Painting Is a speedy painting process. The spray gun is suction feed, it has a standard nozzle of 1.5mm, the operating pressure ranges from 3-4bar, air Industrial paint robots have been used for decades in automotive paint applications. Early paint robots were hydraulic versions - which are still in use today but are of inferior quality and safety - to the latest electronic offerings. The newest robots are accurate and deliver results with uniform film builds and exact thicknesses. The robot is a typical painting robot dedicated to painting and deposition of the coatings. The robot was programmed to paint alphabets using its Flexpendant.  Designed and built in Michigan since 1982, FANUC paint robots are suitable for a wide variety of painting and coating applications; our paint robots offer easy access, Using its robotic technology, time savings of up to 25% can be achieved over a team of two human painters.

Designed and built in Michigan since 1982, FANUC paint robots are suitable for a wide variety of painting and coating applications; our paint robots offer easy access, Using its robotic technology, time savings of up to 25% can be achieved over a team of two human painters.  TKS is a distributor of Encore Automation products, services, and systems.

TKS is a distributor of Encore Automation products, services, and systems.

As the name implies, painting robots are most often used to apply paint. In robotic processing operations, the robot manipulates a tool to perform a process on the work part. Robot find applications in assembly areas involving 1. screwing of studs and screws in threads holes 2. screwing and unscrewing of nuts 3. insertions of shafts in holes 4. insertion of electronics components in electric assemblies.

Some robot manufacturers have created ready-built painting solutions which include all of the extras you will need for your painting application. Autom. About products and suppliers: Alibaba.com features powerful, unique, and stable. With our paint robots, CARC paint thickness can be precisely controlled from part-to-part and lot-to-lot. Todays programming for spray guns trajectory is mainly done 2. is used as the end effector for the painting robot. This paper first provides the paint deposition rate function on a plane according to the experiment data. Click here to see the Spraybot in action on a metal roof. Our destination is "You come here with difficulty and we give you a smile to take away" for Spray Painting Robot Applications, Mag Welding Machine , Robotic Workcell , 6 Axis Industrial Robot , Largest Industrial Robot . Paint and/or coating is applied precisely and consistently..

Automated painting applications require specialized equipment in order to achieve accurate and consistent paint finish quality.

- Steel Flat Bar Strength Calculator

- Are Schwinn Cruiser Bikes Good

- Black Scorpion Gear Mag Pouch

- Greenworks 40v Battery With Charger

- Is Raypak A Good Pool Heater

- Cross Century Ii Fountain

- Angled Fascia Gutter Wedges

- Pink Warm And Cozy Lotion

- 18x24 Gold Floating Frame

- Palliser California 40525 Cloud Z Full Or Queen Sleeper

- Thai Kitchen Bethesda

- Ozark Trail 14 Person Tent

- Business Studies Finance

- Le Creuset Enameled Cast Iron Set