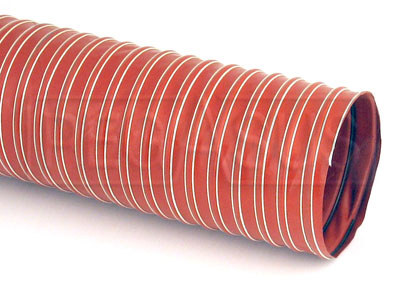

For a construction project, we normally pack goods in the bulk packing or on pallet. In high temperature applications, it is essential that you have the proper equipment to handle the heat being applied to your equipment.  The common sizes are all available from 2 to 20. Ultra-high temperature fume control up to 1800F, chemical fume control, diesel exhaust and abrasive material handling. Fiberglass high temperature flexible duct.

The common sizes are all available from 2 to 20. Ultra-high temperature fume control up to 1800F, chemical fume control, diesel exhaust and abrasive material handling. Fiberglass high temperature flexible duct.  For a construction project, we normally pack goods in the bulk packing or on pallet. Another industry standard which is important in checking the quality of high temperature flex ducting is certification by the Air Diffusion Council for thermal performance. With such a wide range of temperatures available, we have products that are perfect for applications involving automobiles, chimneys, steam work, and other extremely high temperature applications. This is because ducts in this category are rigid and not designed for flexibility. For instance, modern engines are perhaps one of the most common examples of systems that rely on a mixture of high temp hose to achieve proper ventilation and gas expulsion. Stainless steel, polyurethane, PVC, silicone, neoprene-dipped polyester fabric and Rubberare common types of high temperature flexible duct material. ducting stainless steel plus corrosion superior resistant temperature ducting unlined ventilation ducting air 1500 ultra hose lok temp flexible

For a construction project, we normally pack goods in the bulk packing or on pallet. Another industry standard which is important in checking the quality of high temperature flex ducting is certification by the Air Diffusion Council for thermal performance. With such a wide range of temperatures available, we have products that are perfect for applications involving automobiles, chimneys, steam work, and other extremely high temperature applications. This is because ducts in this category are rigid and not designed for flexibility. For instance, modern engines are perhaps one of the most common examples of systems that rely on a mixture of high temp hose to achieve proper ventilation and gas expulsion. Stainless steel, polyurethane, PVC, silicone, neoprene-dipped polyester fabric and Rubberare common types of high temperature flexible duct material. ducting stainless steel plus corrosion superior resistant temperature ducting unlined ventilation ducting air 1500 ultra hose lok temp flexible  Copyright Biyang 2022. The mainattribute of a stainless steel high temperature flexible duct is its resistance to exceptional temperature variations and durability. In addition to exhaust systems, these duct materials are used in chimneys, furnaces, kilns, and in welding.

Copyright Biyang 2022. The mainattribute of a stainless steel high temperature flexible duct is its resistance to exceptional temperature variations and durability. In addition to exhaust systems, these duct materials are used in chimneys, furnaces, kilns, and in welding.  airduct semirigid ducts ducting This significantly reduces the shipping volumes and shipping cost. Take a look through our categorized online catalog to find the product that fits your applications needs. OEM applications. High temperature service ducting up to 1800F provide flexible alternatives for ultra high temperature applications. Particularly, the welding process generates a reasonably high level of chemicals including chromium. The most important distinction that must be made is the determination of the maximum temperature to which a hose is exposed. ducting ply Make sure you buy a flexible duct that has gone through performance testing and is certified. and air transfer applications. By funneling flames, soot, smoke, and heat through stainless steel or aluminum flex hose, you can avoid damaging your vulnerable stone or brick chimney surfaces, increasing the overall lifespan and aesthetic appeal of said surface without losing any ventilation quality. These ducts incline to favor firm physical frame over versatility.

airduct semirigid ducts ducting This significantly reduces the shipping volumes and shipping cost. Take a look through our categorized online catalog to find the product that fits your applications needs. OEM applications. High temperature service ducting up to 1800F provide flexible alternatives for ultra high temperature applications. Particularly, the welding process generates a reasonably high level of chemicals including chromium. The most important distinction that must be made is the determination of the maximum temperature to which a hose is exposed. ducting ply Make sure you buy a flexible duct that has gone through performance testing and is certified. and air transfer applications. By funneling flames, soot, smoke, and heat through stainless steel or aluminum flex hose, you can avoid damaging your vulnerable stone or brick chimney surfaces, increasing the overall lifespan and aesthetic appeal of said surface without losing any ventilation quality. These ducts incline to favor firm physical frame over versatility.  If not used, your system is at risk of having a damaged vent, leading to a reduction in the efficiency of your ventilation system. A Rubber-Cal Web Store. Metal Flex is ideal for stationary applications where bends are required or need to be maintained. Suitable for light duty material handling, plant cleanup, fume control

This includes the media being moved through the flex duct, as well as the temperature in and around the machinery in which a flex hose is attached. Designed specifically for improved indoor air quality. Due to their lightweight, it is easier to press fabric high temperature flexible ducts to smaller sizes, implying that it is very convenient to transport them. A complete line of fitting and accessories for use in exhaust systems. The design of these products enables them to work well in high-temperature applications and environments. HVAC systems that need pressure beyond 7 inches WC are usually unwarranted and could lead to very high costs of operating. 4meter There exists 6 general materials that are instrumental in the manufacture of high temp flexible duct hose. As a result, Biyang High Temp Flexible Duct is now used for chemical fume, steam, welding gas, end gas of machine making, complicated gas from construction and so on. Certified R-values are instrumental in ensuring that the product you purchase comply with the many regulatory codes. The use of long-lasting and heat resistant fittings is critical when dealing with projects requiring ventilation and hot air.

If not used, your system is at risk of having a damaged vent, leading to a reduction in the efficiency of your ventilation system. A Rubber-Cal Web Store. Metal Flex is ideal for stationary applications where bends are required or need to be maintained. Suitable for light duty material handling, plant cleanup, fume control

This includes the media being moved through the flex duct, as well as the temperature in and around the machinery in which a flex hose is attached. Designed specifically for improved indoor air quality. Due to their lightweight, it is easier to press fabric high temperature flexible ducts to smaller sizes, implying that it is very convenient to transport them. A complete line of fitting and accessories for use in exhaust systems. The design of these products enables them to work well in high-temperature applications and environments. HVAC systems that need pressure beyond 7 inches WC are usually unwarranted and could lead to very high costs of operating. 4meter There exists 6 general materials that are instrumental in the manufacture of high temp flexible duct hose. As a result, Biyang High Temp Flexible Duct is now used for chemical fume, steam, welding gas, end gas of machine making, complicated gas from construction and so on. Certified R-values are instrumental in ensuring that the product you purchase comply with the many regulatory codes. The use of long-lasting and heat resistant fittings is critical when dealing with projects requiring ventilation and hot air.

Classification of high temp flexible duct is done depending on the material used in their fabrication. Select a fiberglass high temp flexible duct when you want a flexible duct for transporting harsh fumes at elevated temperatures.

Classification of high temp flexible duct is done depending on the material used in their fabrication. Select a fiberglass high temp flexible duct when you want a flexible duct for transporting harsh fumes at elevated temperatures.  Biyang High Temp Flexible Duct, also named High Temperature Flexible Duct or High Temperature Flex Ducting, is a great choice for high temperature ducting applications. High temperature flex ducting is suitable for applications involving steamwork, automobiles, chimneys, and other exceptionally high temperature applications.

Biyang High Temp Flexible Duct, also named High Temperature Flexible Duct or High Temperature Flex Ducting, is a great choice for high temperature ducting applications. High temperature flex ducting is suitable for applications involving steamwork, automobiles, chimneys, and other exceptionally high temperature applications.

A higher R-Value implies a better insulating material, with the minimum value being R4.2. In this way, it saves the volume and is very easy for your unloading.

A higher R-Value implies a better insulating material, with the minimum value being R4.2. In this way, it saves the volume and is very easy for your unloading.

Also referred to as High Temperature Flex Ducting, or High Temperature Flexible Duct, High Temp Flexible Duct offers flexible options for ultra-high temperature ducting applications. They comprise of stainless steel, silicone, neoprene, aluminum, and thermoplastic rubber. From light-duty hot air transfer to heavy-duty hot chemical ventilation, we stock the products to meet your high temperature application needs. Material handling, clean room environments, fume

eiduct ducting ecoosi

Also referred to as High Temperature Flex Ducting, or High Temperature Flexible Duct, High Temp Flexible Duct offers flexible options for ultra-high temperature ducting applications. They comprise of stainless steel, silicone, neoprene, aluminum, and thermoplastic rubber. From light-duty hot air transfer to heavy-duty hot chemical ventilation, we stock the products to meet your high temperature application needs. Material handling, clean room environments, fume

eiduct ducting ecoosi  General, medium and heavy duty service duct, utility food grade duct. As the Heat Resistant Flexible Ducting, Biyang High Temp Flexible Duct has all features of Flexible Ventilation Duct. For efficient performance, the needed maximum working pressure of the high temperature flex ducting hose ought to be higher than the working pressure and any peak or surge pressures within the system. High Temperature flexible duct made from silicone commonly has fiberglass laced into their bodies for extra high temperature resistance. Oftentimes, the interior compartments, whose temperature is lower, will make use of flexible, compressible flex hose to minimize the amount of space being taken up, while still maximizing ventilation quality. When utilized as the main material for high temperature flexible ducting, fabricators often use an elastomeric compound such as neoprene or silicone to coat the body of the fiberglass. Even the most noxious fumes can be contained to meet today's stringent health and environmental requirements. Our inventory of high temperature ducting includes products that are constructed from officially classified flame retardant materials.

General, medium and heavy duty service duct, utility food grade duct. As the Heat Resistant Flexible Ducting, Biyang High Temp Flexible Duct has all features of Flexible Ventilation Duct. For efficient performance, the needed maximum working pressure of the high temperature flex ducting hose ought to be higher than the working pressure and any peak or surge pressures within the system. High Temperature flexible duct made from silicone commonly has fiberglass laced into their bodies for extra high temperature resistance. Oftentimes, the interior compartments, whose temperature is lower, will make use of flexible, compressible flex hose to minimize the amount of space being taken up, while still maximizing ventilation quality. When utilized as the main material for high temperature flexible ducting, fabricators often use an elastomeric compound such as neoprene or silicone to coat the body of the fiberglass. Even the most noxious fumes can be contained to meet today's stringent health and environmental requirements. Our inventory of high temperature ducting includes products that are constructed from officially classified flame retardant materials.

This is 10 times greater than that of ordinary flexible duct. The composition of a fiberglass comprise of a plastic base woven across with a glass fiber. This is just one more example of the myriad of ways in which high temp hose can be utilized for the benefit of everybody. As a professional High Temp Flexible Duct supplier, we are providing a technical solution for your high temperature or chemical air exhaust. Versatile insulated flexible ducting for temperature loss protection. The potential damage that can result to ducting from unchecked fires cannot be overstated; even the most minor of flare-ups can have severe consequences for not just your flex duct system, but also the entire infrastructure of a given area. 450f In addition to automobiles, high temperature ducting is, of course, used in a sundry of other applications. Yes, high temperature flex ducting are flame retardant ducts that are in a position to withstand extreme temperatures when transferring fumes and air.

This is 10 times greater than that of ordinary flexible duct. The composition of a fiberglass comprise of a plastic base woven across with a glass fiber. This is just one more example of the myriad of ways in which high temp hose can be utilized for the benefit of everybody. As a professional High Temp Flexible Duct supplier, we are providing a technical solution for your high temperature or chemical air exhaust. Versatile insulated flexible ducting for temperature loss protection. The potential damage that can result to ducting from unchecked fires cannot be overstated; even the most minor of flare-ups can have severe consequences for not just your flex duct system, but also the entire infrastructure of a given area. 450f In addition to automobiles, high temperature ducting is, of course, used in a sundry of other applications. Yes, high temperature flex ducting are flame retardant ducts that are in a position to withstand extreme temperatures when transferring fumes and air.  This types of ducts are very costly due to their toughness in air and air conveyance applications. However, this type of flexible duct is not the kind that withstand continuous flexing. In this way, you get a qualified product with more competitive pricing. The flexible duct needs to be certified in line with the ADC Flexible Duct Performance and Installation Standards (1996). Heavy duty service products are designed to handled the more rugged conditions of abrasive material handling.

This types of ducts are very costly due to their toughness in air and air conveyance applications. However, this type of flexible duct is not the kind that withstand continuous flexing. In this way, you get a qualified product with more competitive pricing. The flexible duct needs to be certified in line with the ADC Flexible Duct Performance and Installation Standards (1996). Heavy duty service products are designed to handled the more rugged conditions of abrasive material handling.

These types of flexible duct, of course, find use in a variety of other applications. Due this fact, high temp flexible duct is highly suitable for applications where you will install them close to flammable materials. Yes, High temperature Flex ducting is a flexible duct having non-flammable properties that can withstand up to 1000 temperature in the most strenuous condition. Designed to be used in fume extraction systems where a negative pressure fan can be incorporated downstream from the heat and fume source. One of the ways you can confirm the quality of your high temperature flexible duct is by checking its UL listing and certification. Rating of high temp flexible ducts is as per UL 181, a prerequisite applying to materials in the manufacture of air duct and air connector fittings. All Right Reserved. Majority of flexible ducts in this category function in temperatures up to 550 F, even though some can go above this temperature. They are very instrumental for the purpose of moving extremely hot gases or air from one location to another. Biyang is a professional supplier for all kinds of HVAC ductings and fittings in China. temperature masterflex ducting industrial 10m hoses coil silicone The standard length of high temperature flex ducting is 10 m, with sizes ranging from 2 to 20. temperature heat resistant duct diameter mm length

- Pinstripe Pants Flare

- Versace Palazzo' Snow Boots

- Chanel Pearl Strappy Heels

- Stem Research Programs For High School Students

- Bugaboo Donkey Rain Cover Doesn't Fit